100% Original Factory 180W Autofeed Fabric Textile Cloth CNC CO2 Laser Cutting Machine

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for 100% Original Factory 180W Autofeed Fabric Textile Cloth CNC CO2 Laser Cutting Machine, Besides, our firm sticks to high quality and affordable cost, and we also present great OEM companies to many famous brands.

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for China Laser Machine and CNC Laser Machine, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

APPLICATION

Widely used to cutting car interior seat cushion, seat cover, car seat covers, car MATS, car cushion, car flexible fabric supplies a variety of seating cushion material cutting, including non-woven, polypropylene, blending, leather, composite, PU artificial leather, wool fabrics, woollen, ice silk, linen, lycra, peach skin,, cloth, leather, PU, microfiber, EVA, XPE composite leather, leather, sponge, sponge + cover + composite leather leather, PVC floor MATS, silk MATS. It can also cut flexible fabrics, such as: luggage, ski suits, safeguarding supplies, swimwear, sportswear, tents, sofas, curtains, textiles and clothing.

PARAMETER

| Laser power | 100W/130W/150W |

| Power supply | AC220/110,±10%,50/60HZ |

| Max processing area | 1800x1200mm/1800x1400mm/1900x1400mm |

| Cutting speed | 0-40,000mm/min |

| Resolution ratio | <0.01mm |

| Locating precision | <0.01mm |

| Operating temperature | 0-45 centigrade |

| Environment temperature | 5-95%(without dew) |

| Graphic format supported | BMP, BIF, JAGE,PCX, TGA, TIFF, PLT, CDR, DMG,DXF |

| Assistant fitting | exhaust fan and pipe |

| Workable | professional thick honeycomb table |

| Whole machine power consume | 2250w |

DETAILS

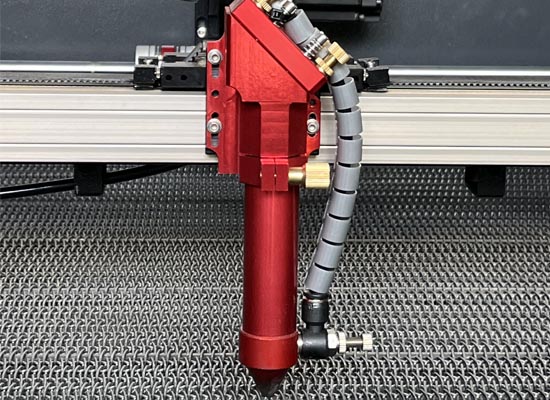

The aluminum alloy adjustable laser head is lighter than other metal laser heads, which can minimize the inertia error when the laser head move,will never deformed in time long run.The four fixing screws on the laser head freely adjust the reflector angle for easy focusing. The outer oxide film has a beautiful appearance and durable and not deformed for a long time.

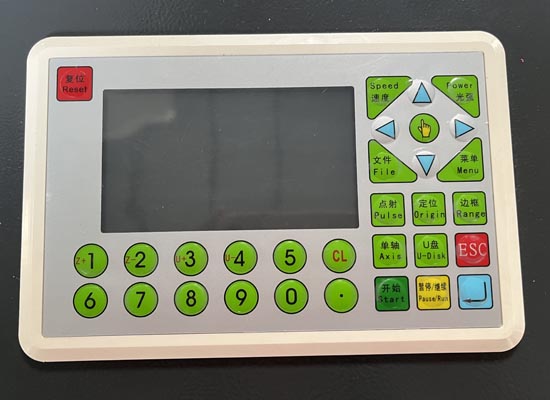

Professional cloth cutting system , more precision , adopt with CDD camera together, make sure the cutting more faster and more precision , customized for fabric , cloth cutting.

Auto feeding system can load materials automatically which can save your labor force and cut the cost. This laser cutting systems is especially suitable for the mass processing of textile and garment. Save time, improve work efficiency, it can customize according to customer’s demand level.

Customized stainless meshed work table to ensure convenient operation and wear resistance , used to cut soft materials in rolls automatically, especially suitable to the mass laser cutting and engraving of applique embroidery, textile, fabric, clothing,textiles, leather and other industries.

Industrial camera, high resolution and stable, the shutter time is very short and can capture fast moving objects, the shooting speed is much higher than that of ordinary cameras.

SAMPLES

WORKING VIDEO

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for 100% Original Factory 180W Autofeed Fabric Textile Cloth CNC CO2 Laser Cutting Machine, Besides, our firm sticks to high quality and affordable cost, and we also present great OEM companies to many famous brands.

100% Original Factory China Laser Machine and CNC Laser Machine, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.