1325 1530 Non-Metal Material Laser Cutting Machine

APPLICATION

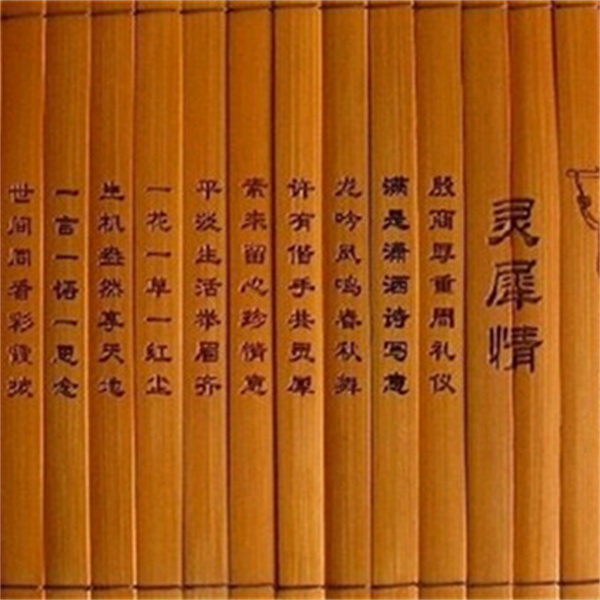

Co2 laser cutter and engraver is professional for non-metal cutting and engraving, suitable for acrylic, double color board, leather, fabric, paper, wooden packing box, bamboo, shell, ivory, rubber, marble and so on.

Co2 laser cutter and engraver is professional for non-metal cutting and engraving, suitable for acrylic, double color board, leather, fabric, paper, wooden packing box, bamboo, shell, ivory, rubber, marble and so on.

| Material | Engraving | Cutting | Material | Engraving | Cutting |

| Acrylic | √ | √ | MDF | √ | √ |

| Double Color Board | √ | √ | Rubber | √ | √ |

| Natural Wood | √ | √ | Plywood | √ | √ |

| Fabric | √ | √ | Plastic | √ | √ |

| Bamboo | √ | √ | Leather | √ | √ |

| Matte Board | √ | √ | Paper | √ | √ |

| Mylar | √ | √ | Fiber glass | √ | √ |

| Press board | √ | √ | Ceramic | √ | × |

| Granite | √ | × | Marble | √ | × |

| Glass | √ | × | Stone | √ | × |

| For special material, please confirm in advance | |||||

PARAMETER

| Working Size:1300*2500mm 1500*3000mm/2000*3000mm |

Tube: 100W/130W/150W/300W |

| Laser Type: CO2 sealed-off glass tube | Laser Tube Brand: Reci / Efr/Yongli/Xinrui |

| Transmission: X axis ball screw + Y axis rack | Operation System and Software: RDC6445G RD works V8 |

| Cooling System: Water cooling | Laser Output Control: 0-100% no section control,soft inner 0-100% adjustable |

| Water Chiller: S&A | Driver and Motor: Pure Servo |

| Engraving Speed:0-1200mm/s | Minimum Letter Size: English:1mm |

| Reposition Accuracy: ≤±0.05mm | Interface: LCD screen with USB interface |

| Transmission Mode: High-precision Taiwan QAQ rack guide rail |

Working Voltage: AC220V/50/60HZ (optional 380V or 110V) |

| Working Environment: Temperature:0-45°C /humidity:5%-80% |

Supported Format: DXF, AI, DST, DWG, BMP, ETC |

FEATURES

1.Precise guide rails ensure accurate and error-free operation. The pioneering continuous, fast curve cutting and shortest processing path optimization improve work efficiency; stabilized constant current laser power supply components to extend life of the laser tube.

2.Bed made from 8mm thick and 100mm wide square pipe, won't be deform, maintain high precision for long time.

3.Racks and gears are precisely ground, wear-resistant and high-precision.

4.Helical gear reducer is 81π(not 31π), much better quality and high precision.

5.The self-developed upper follow-up ventilation patent, combined with partition ventilation, can effectively suck away the waste gas and irritating gas generated during large-format processing.

6.Machine adopts international DSP technology separated from computer operation; USB interface, supports U disk, USB, network cable transmission mode.

DETAILS

Working Bed: Fine milling process for every machine bed, ensure machine absolute level, guaranteed high accuracy.

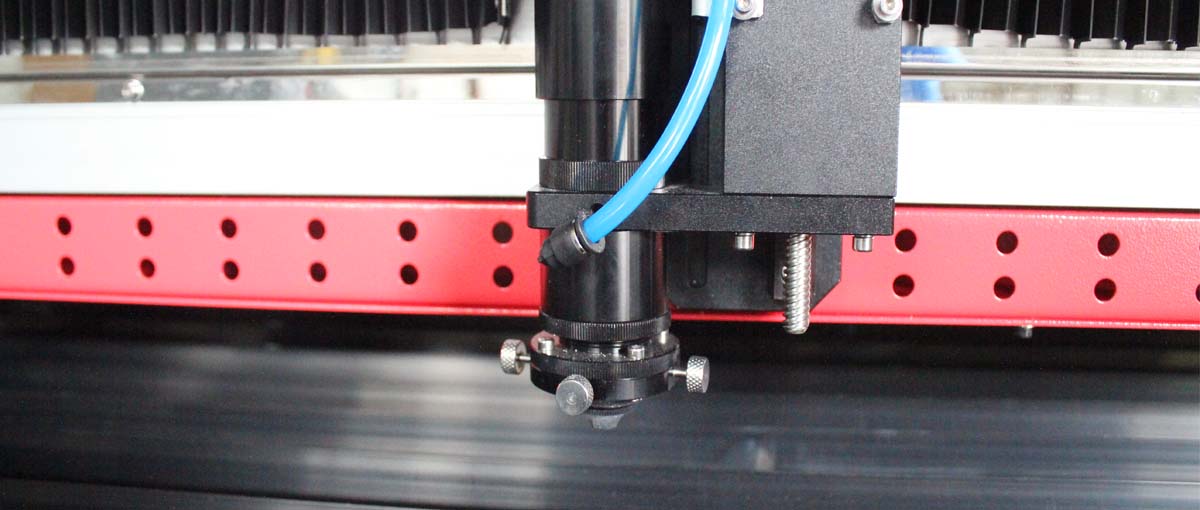

X Axis: It is ball screw transmission for X axis, higher precision, very suitable for Artware industry.

Y Axis: The Y-axis is DIN6 precision level grinding-grade rack, which has higher precision and better stability than traditional belt transmission.

Test device: Balancer, collimator and other detection methods make the machine bed,guide rail and rack level,it is KEY step to ensure a high accuracy machine.

Constant Laser Path: We use a constant laser path of 5 mirrors on this machine, so that the distance between the laser from the laser tube outlet to the material will always remain consistent no matter where the laser head moves.

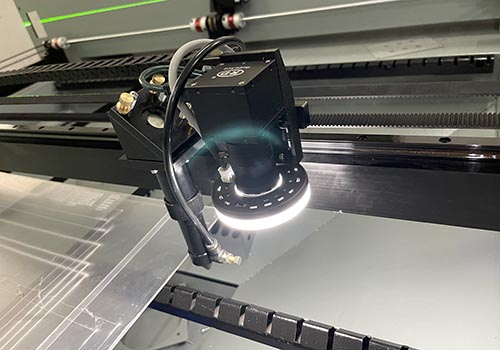

Inbuilt Auto Focus:Specific built-in focus can adjust automatically the focus according to different thick materials,no need change cutting head, suitable for any lens.

SAMPLES

WORKING VIDEO

WORKING VIDEO

Four cutting heads

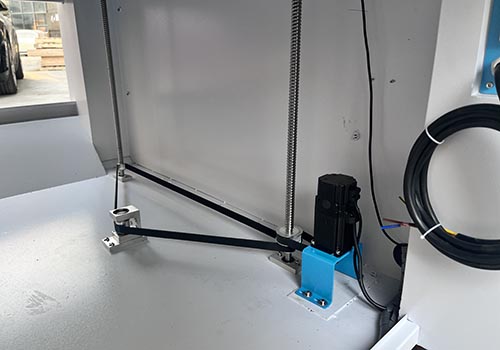

Up and down table

Rotary

Camera

Automatic focus

Fire unit

Indicator light

Red light

TRAINING

We provide free technical training until customer can use the equipment normally. The main training contents are as follows:

1. Basic knowledge and principles of laser.

2. Laser construction, operation, maintenance and upkeep.

3. Electrical principle, operation of CNC system, general fault diagnosis.

4. Laser cutting process.

5. Operation and daily maintenance of machine tools.

6. Adjustment and maintenance of optical path system.

7. Laser processing safety education.