1390 1610 Co2 Laser Cutting Machine With CCD Camera

APPLICATION

Applcation industrial:

Advertising signs,craft gifts,crystal jewelry,paper cutting technology,architectural models,lighting,printing and packaging,electronic appliances,clothing bags,photo frame production and other industries.

Application Materials:

Wood products, Plywood, Acrylic, Plastic, Cloth, Leather, Paper, Rubber, Bamboo, Marble, Double layer plastic, glass, wine bottles etc.

PARAMETER

| Working Size: 600*400mm/600*900mm/1300*900mm//1400*100mm/1600*1000mm | Tube Watts: 80W/100W/130W/150W/200W/300W |

| Laser Type: CO2 sealed-off glass tube | With Camera |

| Operation System: RDC6445G | Driver and Motor: stepper or servo |

| Cooling System: Water cooling | Cutting Speed:0-600mm/s |

| Engraving Speed:0-1200mm/s | Reposition Accuracy: ≤±0.01mm |

| Minimum Letter Size: English:1mm | Compatible software: CorelDraw, AutoCAD, Photoshop |

ADVANTAGE

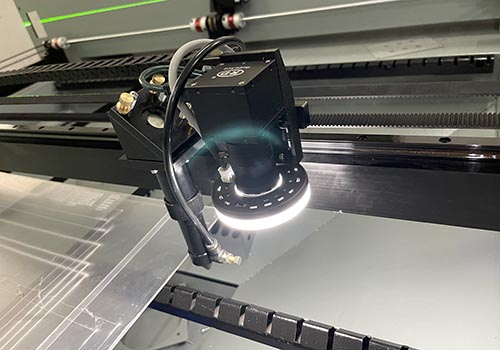

Adopting the combination of automatic camera locating system and laser head, with the assistance of computer software, label cutting machine can compensate automatically to pinpoint deformation of the fabric, it ensures the accuracy of cutting.

The application of camera systems, marking laser technology, automation technology, shortest cutting path of human-based software design, saves time and increases efficiency for user.

DETAILS

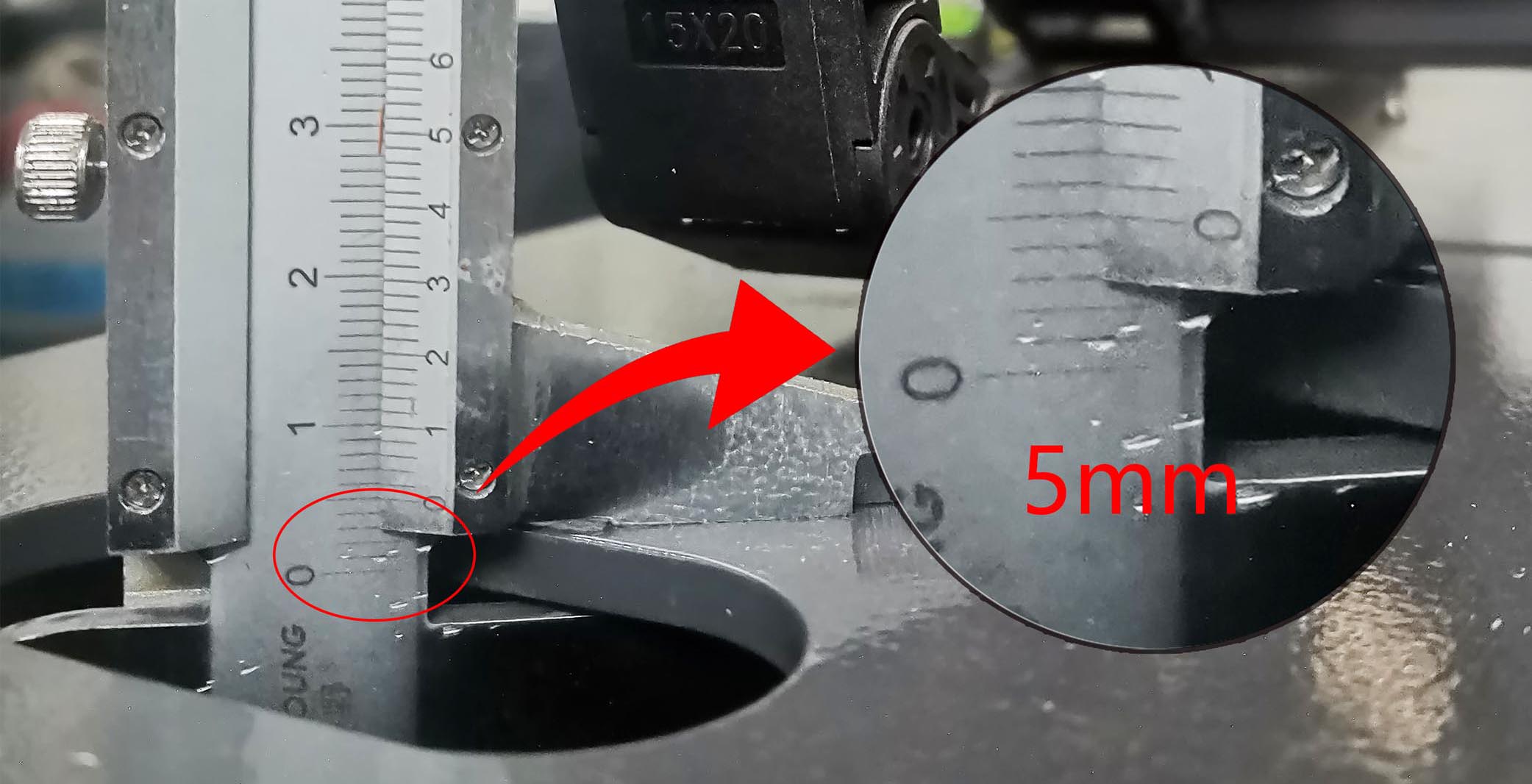

5mm steel plate thickness makes machine more stable, and no deformation after many years.

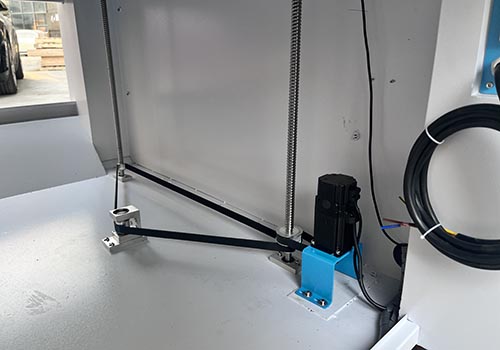

Hardware system, the metal parts and rail and supporting pipe material are all made by No1 brand aluminum material, the material more hard and heavy which will protect machine from deformation even after many years working; More important is more hard and good quality material will ensure laser head working without any vibration and produce higher precision.

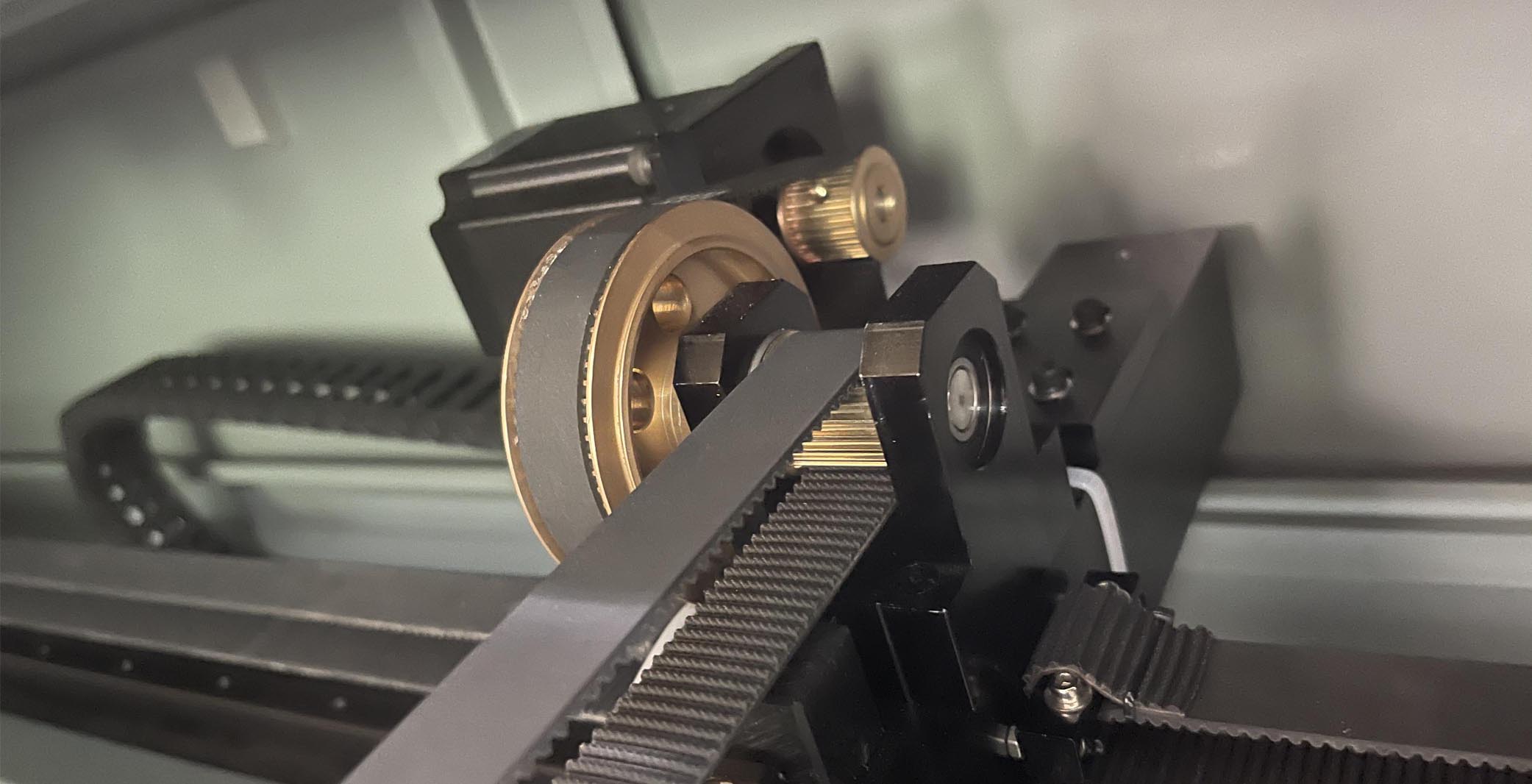

We use copper pully, it can work and keep high precision for long time, not aluminum pully, aluminum pully needs replace after some time working, because pulley teeth easy be used out, and the precision will lower down

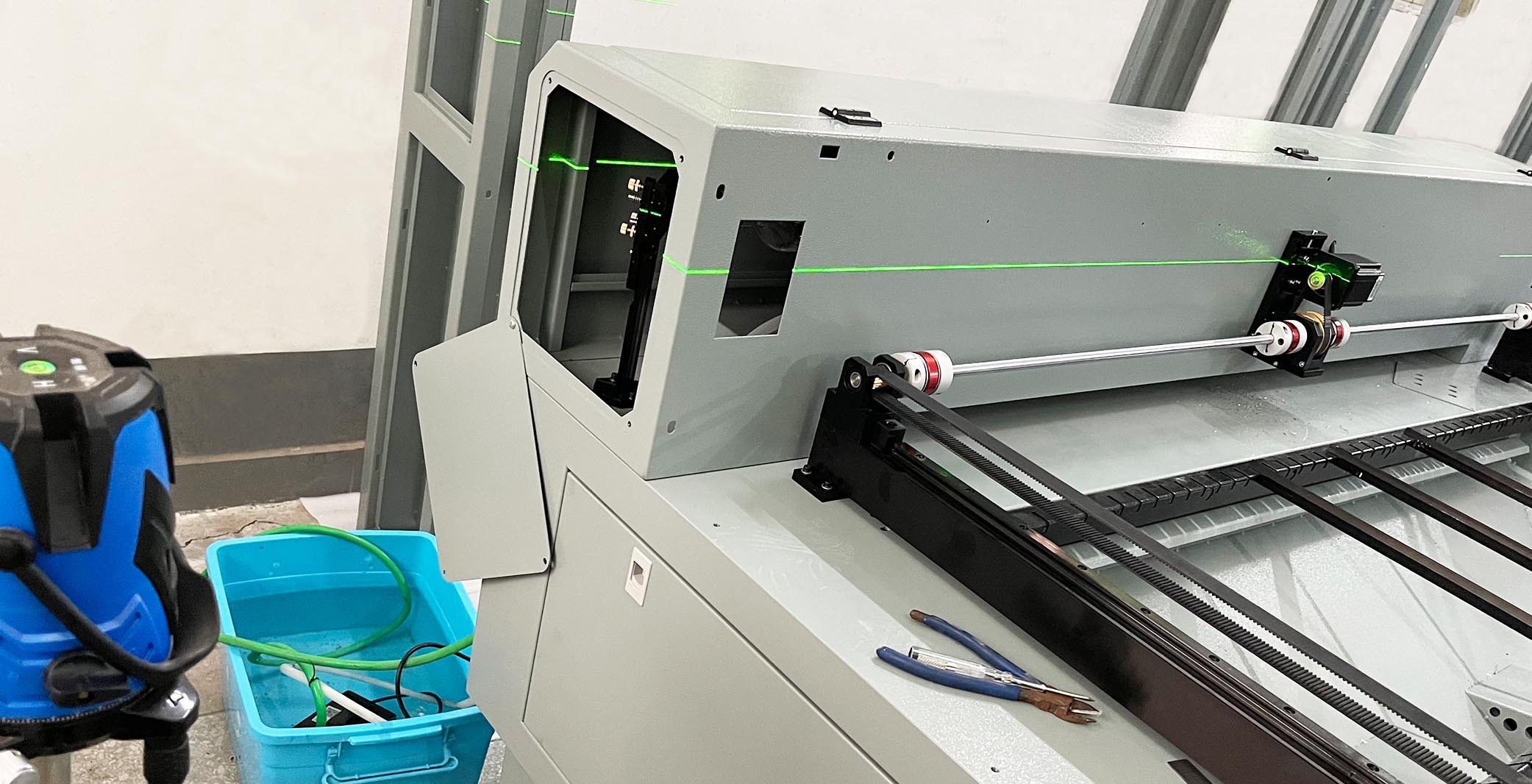

When install rail system, we use professional balancing apparatus to keep rail 100% level, ensures machine high precision.

Camera pick-up positioning, scan the material, cutting more efficient and precision

SAMPLES

WORKING VIDEO

WORKING VIDEO

Four cutting heads

Up and down table

Rotary

Camera

Automatic focus

Fire unit

Indicator light

Red light

TRAINING

We provide free technical training until customer can use the equipment normally. The main training contents are as follows:

1. Basic knowledge and principles of laser.

2. Laser construction, operation, maintenance and upkeep.

3. Electrical principle, operation of CNC system, general fault diagnosis.

4. Laser cutting process.

5. Operation and daily maintenance of machine tools.

6. Adjustment and maintenance of optical path system.

7. Laser processing safety education.