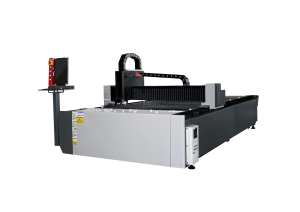

Big Discount Handheld 3 in 1 Fiber Laser Welding Cleaning Cutting Machine 1500W

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Big Discount Handheld 3 in 1 Fiber Laser Welding Cleaning Cutting Machine 1500W, Our merchandise are regularly supplied to many Groups and lots of Factories. Meanwhile, our goods are sold towards the USA, Italy, Singapore, Malaysia, Russia, Poland, plus the Middle East.

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for China 2000W Laser Welding Machine and 1500W Laser Welding Machine, With the superior and exceptional service, we’ve been well developed along with our customers. Expertise and know-how ensure that we’ve been always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

PARAMETER

|

Laser power |

100W/ 200W/500W |

|

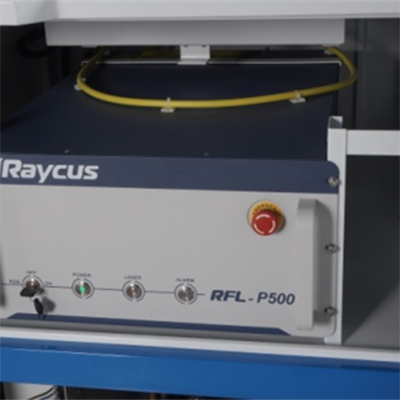

Laser source type |

Raycus, IPG for option |

|

Laser wavelength |

1064 nm |

|

Cooling method |

Water cooling |

|

Cooling water |

Deionized water |

|

Water temperature |

18-22 °C |

|

Scan width |

10-60 mm |

|

Auxiliary gas |

Compressed air/Nitrogen |

|

Air pressure |

0.5-0.8 MPa |

|

Optional accessory |

Handheld / Manipulator |

|

Working condition |

5-40 °C |

FEATURE

- Accurate laser cleaning for exact position and precise size.

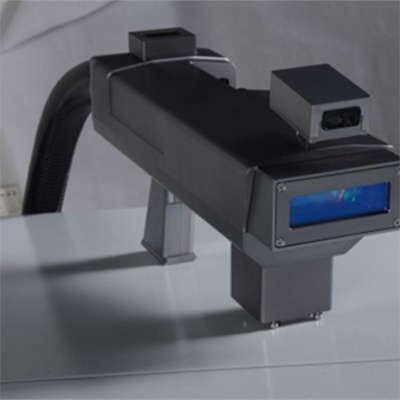

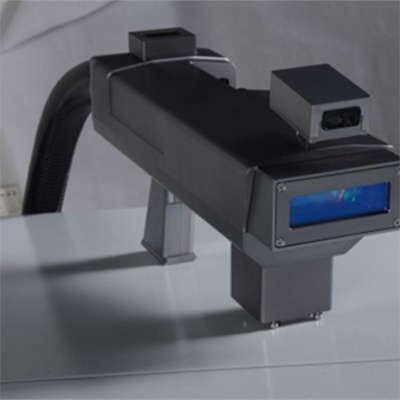

- Flexible operation for work pieces with complicated geometric construction can be realized by hand-held laser cleaning head.

- Widely applied in flat, curved and three-dimensional surface for work piece of elastic material and plastic with very small and deep holes.

- Safe & environment-friendly. Without using chemical detergent or other consumables

- Non-contact cleaning and no damage for substrate Extremely.

- Easy to operate, with portable mode and could be equipped with robot for automatic cleaning

- No maintenance and no consumables, dust-free, no chemicals, no pollution.

- Low cleaning cost and High cleaning efficiency.

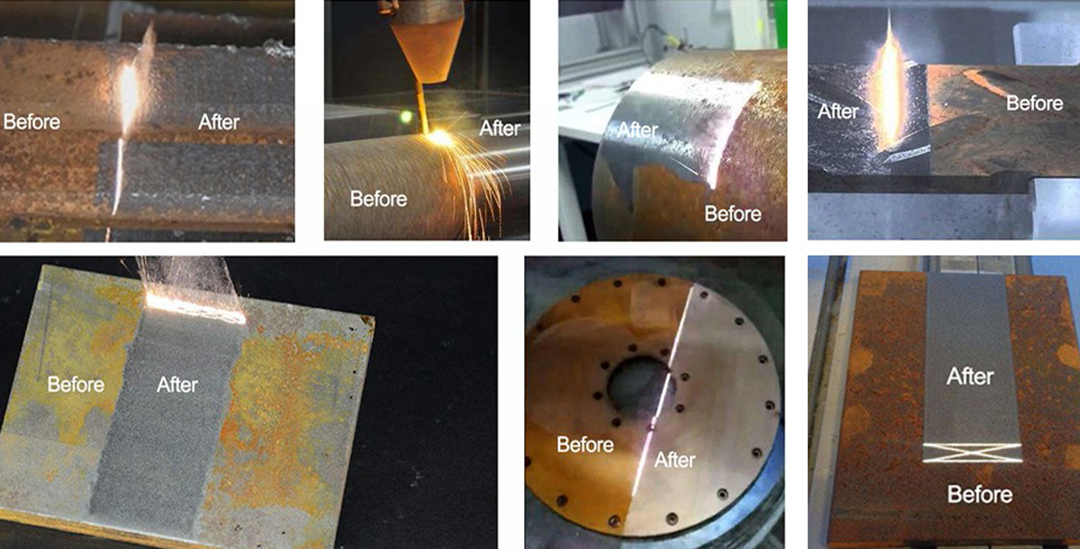

APPLICATION

Metal surface rust removal

Surface paint cleaning

Surface oil stain/contaminant cleaning

Coating surface cleaning

Welding / coating surface pre-treatment

Stone figure surface dust & attachment cleaning

Plastic mould residues cleaning

DETAILS

PRINCIPLE

The difference between continuous laser and pulse laser cleaning:

After pulsed light cleaning, the paint layer on the surface of the sample is completely removed, and the surface of the sample appears. Metallic white, and almost no damage to the sample substrate. After cleaning with continuous light, the paint layer on the surface of the sample was completely removed, but the surface of the sample appeared gray-black, and the substrate of the sample also showed micro-melting. Therefore, the use of continuous light is more likely to cause damage to the substrate than pulsed light.

Both continuous laser and pulsed laser can remove the paint on the surface of the material to achieve the effect of cleaning. Under the same power conditions, the cleaning efficiency of pulsed lasers is much higher than that of continuous lasers. At the same time, pulsed lasers can better control heat input to prevent excessive temperature of the substrate or micro-melting.

Continuous lasers have an advantage in price, and the gap in efficiency with pulsed lasers can be made up by using high-power lasers, but high-power continuous light has greater heat input, and the damage to the substrate will also increase. Therefore, there is a fundamental difference between the two in application scenarios. For applications with high precision, strict control of the temperature rise of the substrate, and non-destructive substrates, such as molds, pulsed lasers should be selected. For some large steel structures, pipelines, etc., due to the large volume and fast heat dissipation, the requirements for substrate damage are not high, and continuous lasers can be selected.

Advantages of pulsed lasers:

Pulsed lasers generate less heat, while continuous lasers generate more heat, which is why high-power lasers use pulses. Pulsed lasers can make the laser generator rest intermittently, while continuous excitation can only make the laser continuously and uninterrupted. work, it is easy to shorten the life of the laser generator.

SAMPLE

VIDEO

Big Discount China 2000W Laser Welding Machine and 1500W Laser Welding Machine, With the superior and exceptional service, we’ve been well developed along with our customers. Expertise and know-how ensure that we’ve been always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.