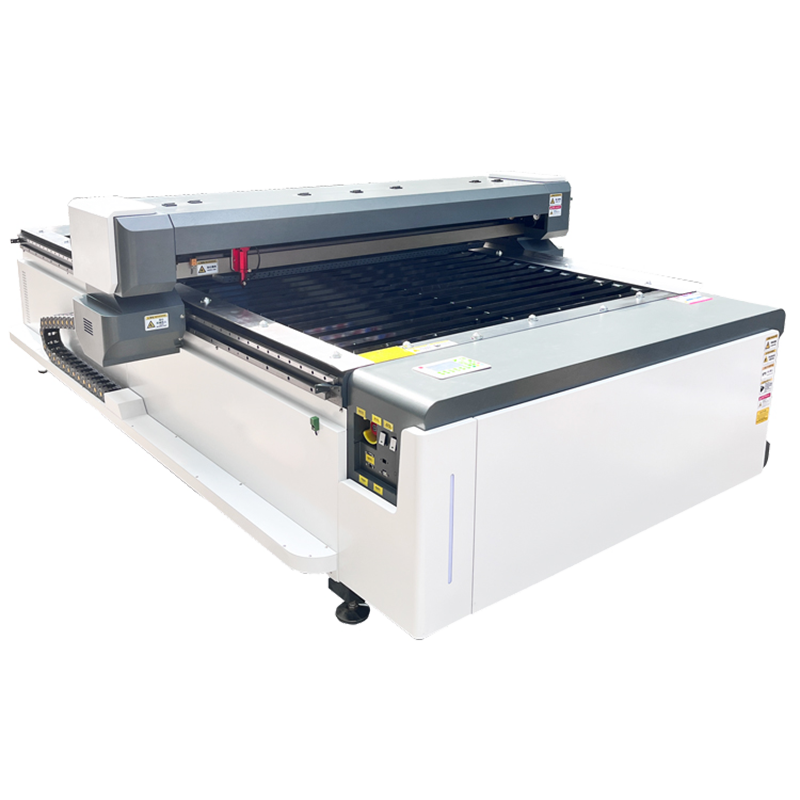

Factory Customized Biggest Discount 1325 1390 Acrylic Laser Cutting Engraving Machine for Wood Plywood Leather Fabric Glove Laser Cutting Machine CO2 Price Automatic Work

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Factory Customized Biggest Discount 1325 1390 Acrylic Laser Cutting Engraving Machine for Wood Plywood Leather Fabric Glove Laser Cutting Machine CO2 Price Automatic Work, Our final goal is “To try the best, To be the Best”. Please feel free to contact with us if you have any requirements.

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for China Auto Feeding Laser and Laser Cutter, We’d like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

APPLICATION

| Material | Engraving | Cutting | Material | Engraving | Cutting |

| Acrylic | √ | √ | MDF | √ | √ |

| Double Color Board | √ | √ | Rubber | √ | √ |

| Natural Wood | √ | √ | Plywood | √ | √ |

| Fabric | √ | √ | Plastic | √ | √ |

| Bamboo | √ | √ | Leather | √ | √ |

| Matte Board | √ | √ | Paper | √ | √ |

| Mylar | √ | √ | Fiber glass | √ | √ |

| Press board | √ | √ | Ceramic | √ | × |

| Granite | √ | × | Marble | √ | × |

| Glass | √ | × | Stone | √ | × |

| For special material, please confirm in advance | |||||

PARAMETER

|

Working Size: 1300*2500mm/ 1500*3000mm |

Tube: 80W/100W/130W/150W/200W/300W |

|

Laser Type: CO2 sealed-off glass tube |

Operation System and Software: RDC6445G RD works V8 |

|

Cooling System: Water cooling |

Driver and Motor: servo |

|

Cutting Speed:0-600mm/s |

Engraving Speed:0-1200mm/s |

|

Reposition Accuracy: ≤±0.01mm |

Minimum Letter Size: English:1mm |

|

X Y Guiding System: Linear guide rails |

Interface: LCD screen with USB interface |

FEATURES

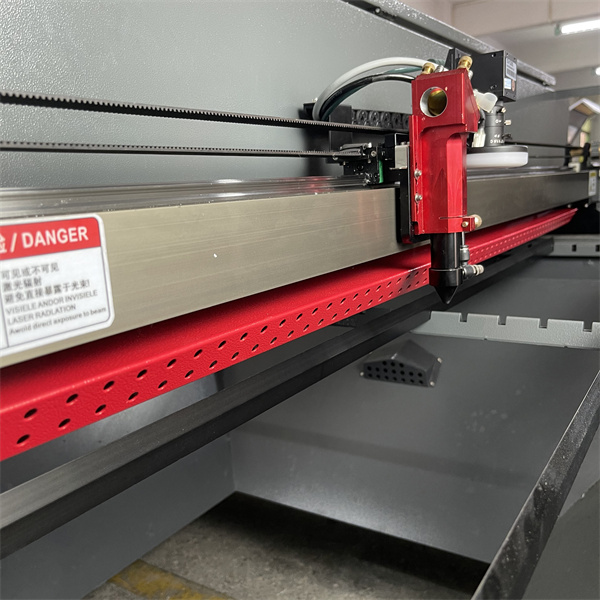

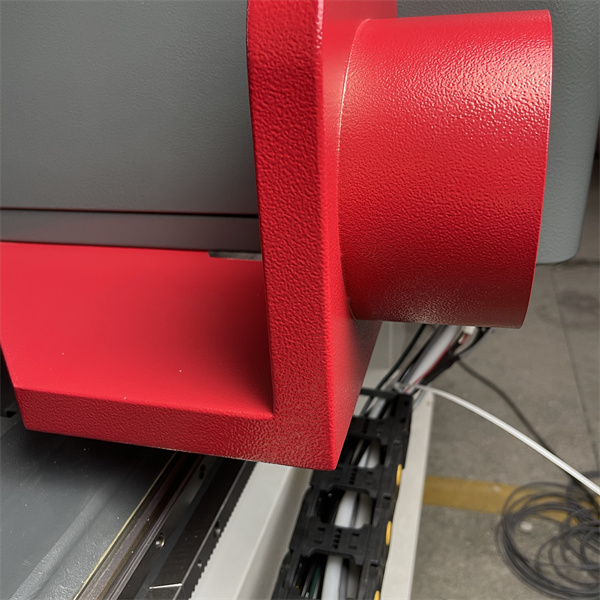

1.Precise guide rails ensure accurate and error-free operation. The pioneering continuous, fast curve cutting and shortest processing path optimization improve work efficiency; stabilized constant current laser power supply components to extend the life of the laser tube.

2.Using triangular structure on the bed’s side, machine is more stable, and high precision.

3.Bed and X-axis beam with 6mm steel, machine’s body is 1.5mm steel, won’t be deform, maintain high precision for long time.

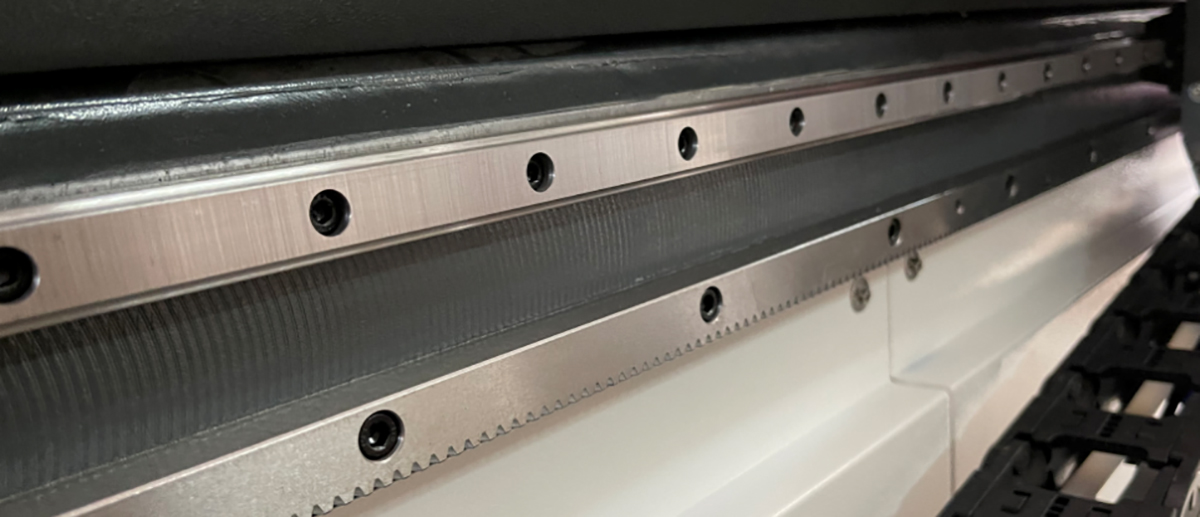

4.Racks and gears are precisely ground, wear-resistant and high-precision.

5.Helical gear reducer is 81π when others use 31π reducer, much better quality and high precision.

6.3 phase motors ensure high speed cutting and good performance.

7. follow-up smoke exhaust system, which can follow the cutting head for smoke exhaust

DETAILS

It adopts a heavy-duty bed structure design, which has increased to 8mm thick steel and better stability compared with the machine’s bed on the market, reaching the top level in the industry.

Three support bars are newly added on the bed. After machining center fine milling, the blades are laid on the support bars without manual adjustment of accuracy, reducing machining errors, making the entire bed structure design more precise than other ordinary machines, and not easy to deform.

Hardware system, the metal parts and rail and supporting pipe material are all made by No1 brand aluminum material, the material more hard and heavy which will protect machine from deformation, without any vibration, ensure produce higher precision.

Racks and gears are precisely ground, wear-resistant and high-precision,the place where the guide rail and rack installed will be fine-milled by the machining center to ensure absolute flatness

Intelligent follow-up smoke exhaust system, which can follow the cutting head for smoke exhaust.

SAMPLES

WORKING VIDEO

WORKING VIDEO

TRAINING

We provide free technical training until customer can use the equipment normally. The main training contents are as follows:

1. Basic knowledge and principles of laser.

2. Laser construction, operation, maintenance and upkeep.

3. Electrical principle, operation of CNC system, general fault diagnosis.

4. Laser cutting process.

5. Operation and daily maintenance of machine tools.

6. Adjustment and maintenance of optical path system.

7. Laser processing safety education.

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Factory Customized Biggest Discount 1325 1390 Acrylic Laser Cutting Engraving Machine for Wood Plywood Leather Fabric Glove Laser Cutting Machine CO2 Price Automatic Work, Our final goal is “To try the best, To be the Best”. Please feel free to contact with us if you have any requirements.

Factory Customized China Auto Feeding Laser and Laser Cutter, We’d like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.