Fiber Laser Cutting Machine JZ1530EH

Voide

PARAMETER

| Model | JZ1530 |

| Laser power | 1000---6000w |

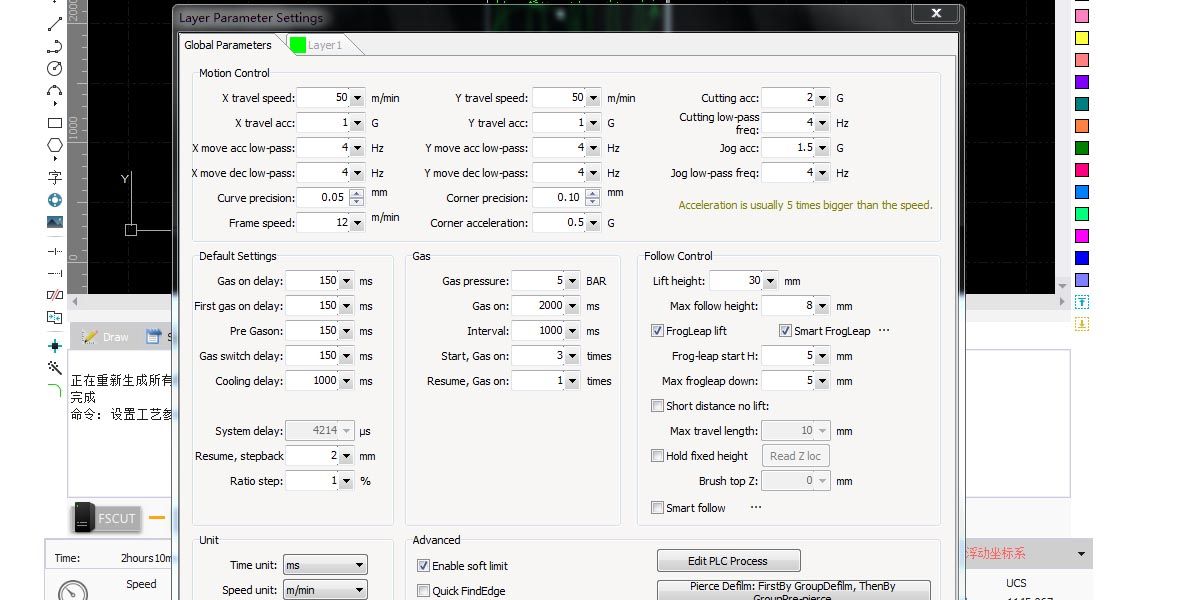

| CNC Control system | Cypcut 2000E |

| Laser source | Raycus/Max/Reci |

| Laser head | Raytool BM110 |

| Drive | Taiwan DELTA servo motors |

| Reducer | Taiwan Faston |

| Transmission | Hiwin/SHAC Lean/APEX rack |

| Laser lens | Raytool |

| Proportional valve | Japan SMC |

| Solenoid valve | Japan SMC |

| Max cutting acceleration | 2G |

| Resolution ratio | 0.025mm |

| Re-position precision | ±0.02mm |

| Power requirement | 220/380V, 50/60HZ |

| Applicable material | stainless steel, carbon steel, galvanized sheet, iron, aluminum, brass, copper |

| Auxiliary gas | Pure air or Oxygen or Nitrogen |

| Graphic supported | DXF、DWG、JPGE、PCX、AI、TIFF、PLT、CDR、BMP |

| Computer with original laser software | WIFI function available |

APPLICATION

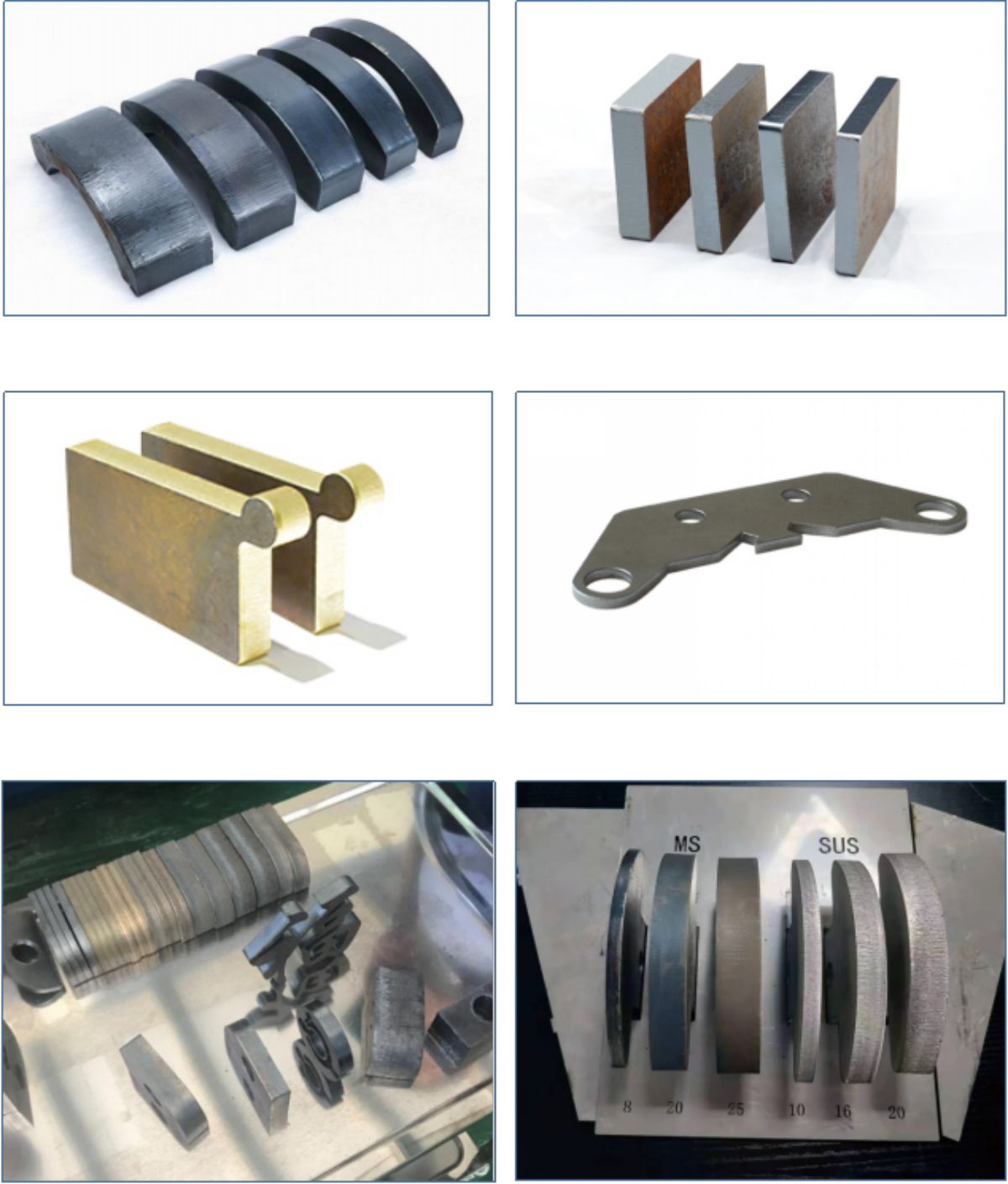

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: JZ Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.ensure that it can operate possible during the laser cutting process.

DETAILS

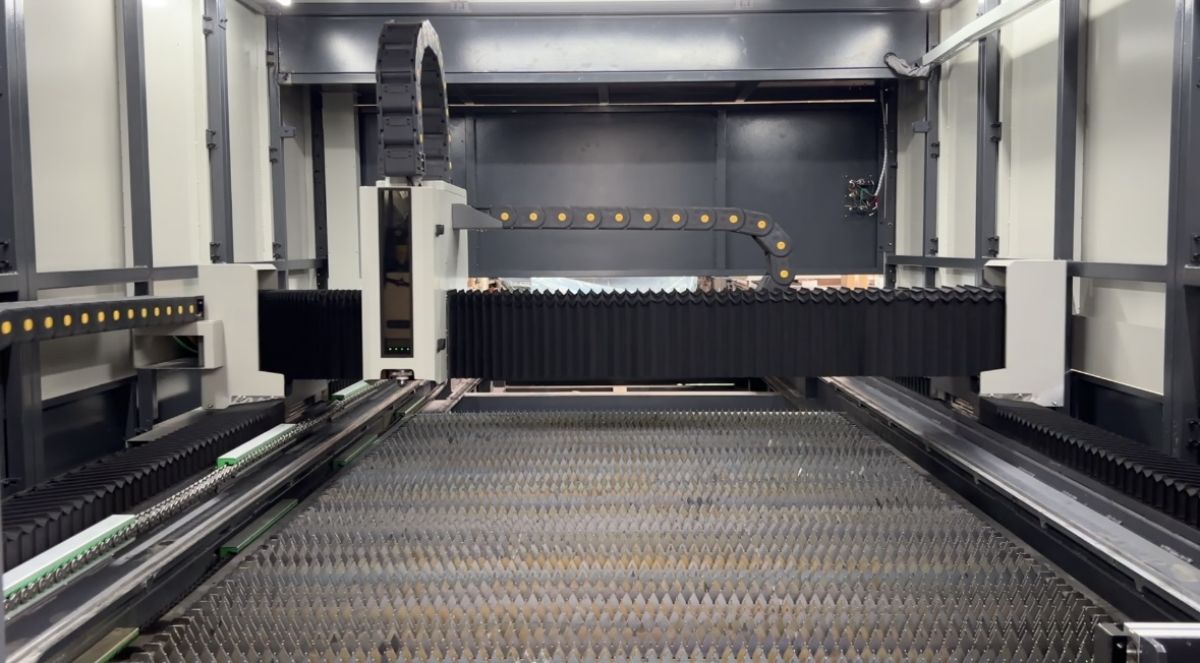

Bed Structure

The bed is made of large thick square pipe and then integrally welded and formed, and then undergoes stress annealing treatment, vibration aging treatment, semi-finishing, and finishing processes. The entire process completely solves the problem of stress deformation caused by welding and processing.

Imported large CNC machining equipment is used to precision mill the entire bed, ensuring the accuracy and stability of the bed and providing customers with a strong guarantee for long-term, batch, and stable cutting.

Beam

The one-piece beam is quenched and tempered to reduce internal stress and brittleness, adjust the mechanical properties of the beam, and improve the stability of the beam.

Z-axis

The Z-axis ball screw is driven by a servo motor to realize the up and down reciprocating motion of the cutting head. There are two control methods that complement each other; achieving high precision in laser cutting, stable cutting quality, and ensuring the quality of the cutting section.

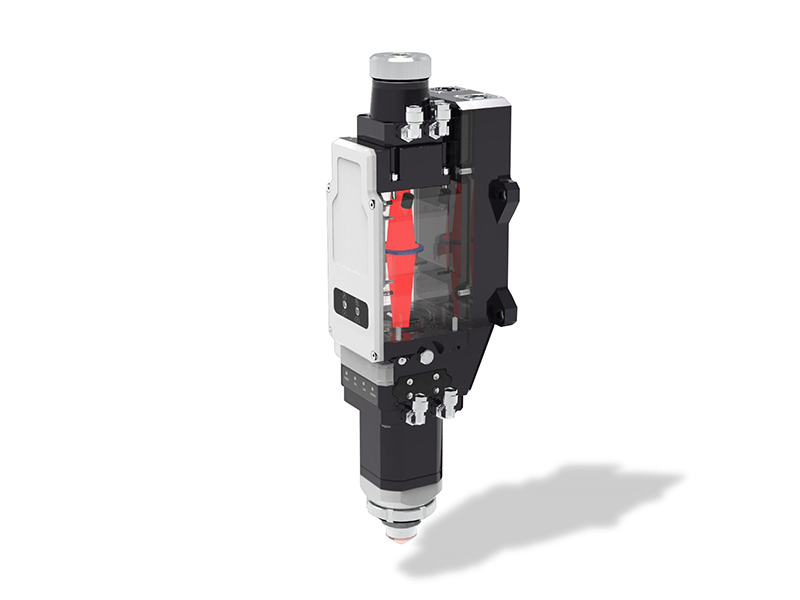

Cutting Head

Automatic focusing cutting head

The new optical solution, automatic focusing, reducing human intervention, nozzle cooling and sensor water cooling make cutting more stable and efficient. Built-in multiple sets of sensors, real-time closed-loop intelligent monitoring, quick diagnosis of problems and early warning.

Laser Source

Famous laser source, laser source is highly integrated, easy to operate, small and lightweight, easy to install, basically maintenance-free in operation, has long-term operation stability and long working life.

Max Cutting Acceleration

2G Max cutting acceleration, take short time from low-speed cutting to high-speed cutting, cuts corners or turning points more smoothly.

Smoke Exhaust System

The closed cutting platform improves purification efficiency and reduces lens pollution. The smoke exhaust device automatically senses and turns on intelligent smoke exhaust, powerful smoke exhaust, and efficient dust removal.

Exchanged Working Table

The double worktables can exchange at the same time, metal plate cutting and loading and unloading can be carried out at the same time, saving loading and unloading time; the gear and rack transmission method is stable and highly precise, and is more efficient than the traditional sprocket chain transmission.

SAMPLES