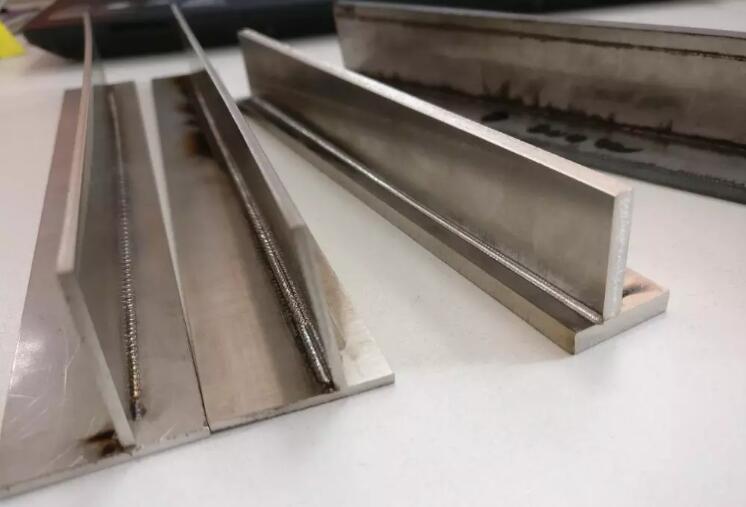

Handheld welding, the use of a handheld fiber laser welder, is flexible and efficient, and the welding distance is longer. Use a handheld soldering gun to change the previously fixed light path. Hand-held fiber laser welders are increasingly used for long laser distances and large applications. Since the area affected by heat during welding is small, there is no deformation of the workpiece, darkening, or marks on the back side. Furthermore, the weld depth is deep, the weld is strong, and melting is sufficient. There are no protrusions in the liquid pools or dents in the base material.

Manual laser welding machine has the advantages of simple operation, beautiful weld, high welding speed and no consumption. It can replace conventional argon welding, electric welding and other processes for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials.

The handheld laser welding machine can be widely used in complex and irregular welding processes in cabinets, kitchens, stair lifts, warehouses, ovens, stainless steel door window covers, distribution boxes, stainless steel houses, etc.

The working method of the handheld fiber laser welding machine is simple, handheld welding, flexible and efficient, and the welding distance is long.