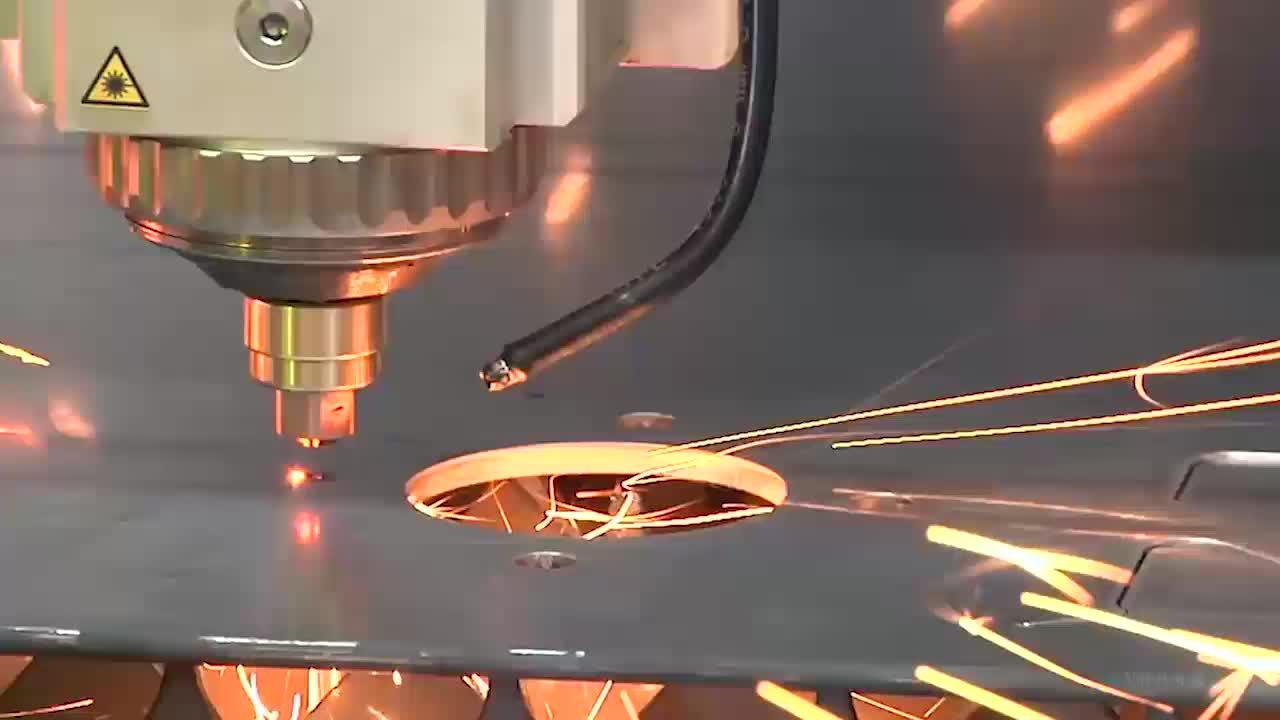

The main factors that make a laser cutting machine effective are:

1. The size of the spot when the laser beam passes through the focus

The small spot when you focus on the laser, which is very precise, especially the small crack, the spot can reach 0.01mm.

2. The accuracy of the workbench determines the repeatability of the cut.

The higher the accuracy of the workbench, the higher the precision.

3. The larger the part, the lower the accuracy and the larger the difference.

Since the laser beam is turned on, the crack is also turned on. 0.3mm stainless steel is smaller than the 2mm hole.

4. The material of the workpiece has some influence on the accuracy of laser cutting.

Under the same conditions, stainless steel has a higher cleaning capacity and a softer finish than aluminum.

5. The cutting quality of the laser cutting machine is good. The cutting width is narrow (generally 0.1–0.5mm), the precision is high (generally, the center hole error is 0.1–0.4mm, the measurement error is 0.1–0.5mm), and the surface roughness the incision. good (generally, Ra is 12.5–25μm), holes can generally be welded without additional processing.