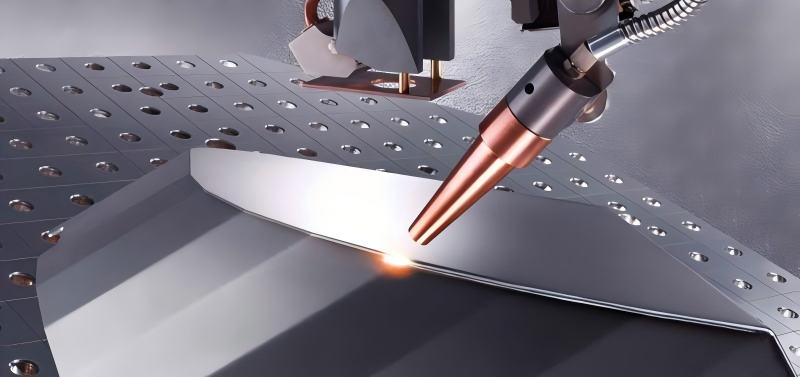

Laser welding equipment is becoming an indispensable core tool in many industries with its advantages of high precision, high efficiency, non-contact processing and diverse applicable materials. From automobile manufacturing to electronic equipment, from aerospace to new energy and then to home appliance manufacturing, the unique performance of laser welding has given new possibilities to the manufacturing industry. Below, let us reveal the main application scenarios of laser welding equipment.

In the automotive industry, laser welding equipment is widely used in the production of key components such as car bodies, chassis, and battery boxes. Since laser welding can accurately control the welding area and achieve deep melting welding, the welded parts are both strong and light, which is very suitable for realizing lightweight design of automobiles. Laser welding can also be used for dissimilar metal welding, combining the characteristics of different materials to further improve the strength and safety of the car body.

The production of electronic products often requires extremely high precision. Laser welding can weld micro components such as battery electrodes, circuit boards, microelectronic components, etc. with micron-level precision. Since laser welding is a non-contact thermal processing method, it has little thermal impact on components and can avoid damage to sensitive components, which is particularly critical in fields such as mobile phones, computers and small electronic devices. In addition, laser welding can be completed in a small space, adapting to the trend of increasingly thin and compact electronic devices.

In the field of new energy, laser welding has important applications in the manufacture of power batteries and photovoltaic modules. The welding in power batteries requires good sealing and firm welding. Laser welding can accurately control the energy output, achieve high sealing connection of the battery shell, and ensure the safety and stability of the battery in use. In addition, the welding of photovoltaic modules also relies on the high efficiency of laser equipment to achieve mass production in a short time, providing reliable support for the development of the new energy industry.